Are you NEW to Precision Slot Die Coating Technology?

What is Slot Die Coating Technology and How do Slot Dies Work?

Introduction

Slot die technology is at the forefront of precision coating solutions, enabling manufacturers across industries to achieve unparalleled accuracy, efficiency, and material savings. Whether you're new to this innovative technology or looking to optimize your current processes, understanding the basics of slot dies is the first step toward unlocking their potential.

Custom slot die solutions are utilized in industries including, but not limited to renewable energy, solar, and lithium-ion batteries to packaging, medical and pharmaceutical applications and everything between.

What is Slot Die Technology?

Slot die technology is a precision coating method used to apply a uniform layer of material onto a substrate or web. This method is highly versatile, accommodating a variety of materials, viscosities, and substrates, including plastics, paper, and metal foils.

Unlike traditional coating methods, slot dies deliver:

-

Superior Uniformity: Achieve coating thicknesses as thin as a micron to millimeters with minimal variation.

-

Reduced Waste: Minimize material usage with precise deposition, lowering costs.

-

Repeatability: Consistent process for precision coating results.

-

Scalability: Adaptable for lab-scale testing and full production runs.

SUBSTRATE

SLOT DIE

FLUID COATING

How Slot Dies Work

Slot dies, also known as flat die heads, use a controlled flow of liquid material dispensed through a precision-engineered die lip. This controlled fluid flow is typically distributed using a fluid delivery system onto a substrate. The substrate moves beneath the die at a consistent speed, ensuring even application.

Critical factors include:

-

Die Lip Design: Controls coating thickness.

-

Fluid Delivery System: Regulates material flow.

-

Process Speed: Synchronizes with substrate movement for uniform coverage.

-

Shim Thickness: OFFSET shims control lip adjustments while BODY shims control coating thickness.

Slot dies can be mounted in any orientation as a part of a coating line or can be integrated into an existing coating line with the use of a slot die coater position equipment.

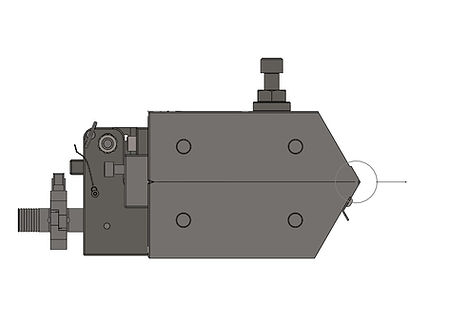

Basic Parts of a Slot Die - External Part 1

A slot coating die consists of several key components essential for its function. The main parts include:

-

the DIE BODY which houses the internal flow path for the coating material.

-

The main structure that houses all other components.

-

Typically made from stainless steel or other corrosion-resistant materials.

-

Provides the necessary rigidity and support for the coating process.

-

All dies have an UPPER DIE BODY and a LOWER DIE BODY

-

Multilayer slot dies can have up to 2 middle sections called a WEDGE or UPPER/LOWER WEDGE. A wedge allows for additional coating capabilities and layers.

-

A DUAL LAYER SLOT DIE has 1 middle wedge

-

A TRIPLE LAYER SLOT DIE has an UPPER wedge and a LOWER Wedge.

-

Due to size constraints, a triple layer slot coating die is the maximum layer capacity PER slot die.

-

-

-

-

-

-

the LIP,

-

The edges of the slot through which the coating material is extruded.

-

Area where the coating exits the die and meets the substrate.

-

-

and the SLOT or SLOT/LIP GAP, which determines the thickness of the coating is located between the UPPER and LOWER BODY LIPS

-

The gap between the lips determines the thickness of the coating.

-

Must be precisely machined and aligned to ensure uniform coating.

-

Additionally, there are adjustment mechanisms for fine-tuning the flow and alignment, as well as mounting brackets for secure installation. Understanding these is crucial for optimizing the coating process in various industrial applications.

SLOT/LIP GAP

UPPER DIE BODY

LOWER DIE BODY

UPPER DIE BODY

LOWER DIE BODY

SLOT/LIP GAP

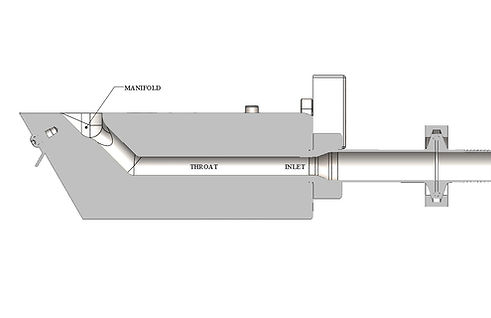

Basic Parts of a Slot Die - Internal

The internal parts of a slot die play a crucial role in the precision and efficiency of slot die coating technology.

Key components are:

-

The INLET

-

The entry point where the liquid coating material enters the slot die system.

-

Typically located at the beginning of the die body and connects to the manifold through the THROAT.

-

Design affects fluid flow rate for consistent coating thickness.

-

-

The THROAT

-

The entry point where the coating fluid enters the die.

-

Typically located in the lower half of the die body.

-

Ensures the fluid is evenly distributed across the width of the die before it flows through the manifold and exits the die lips.

-

-

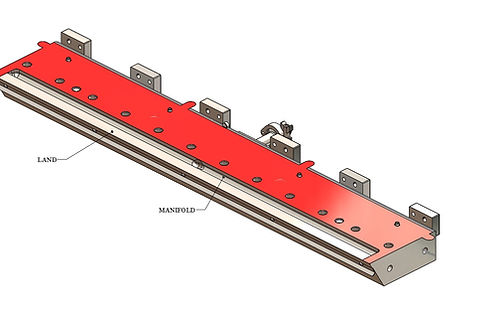

The Lip LAND

-

Design ensure even distribution and control of the coating material, leading to high finishes.

-

Manufacturers providing custom manifold designs allow for tailored solutions that meet specific application requirements, enhancing efficiency and performance.

-

In contrast, manufacturers who provide cookie cutter manifold designs may not address unique needs, leading to inconsistent results. Choosing a manufacturer that specializes in custom designs ensures that you receive coating tooling that maximizes your coating process and minimizes waste.

-

In the slot die coating industry, the design of the manifold and land is crucial for achieving uniform coating thickness and optimal flow characteristics.

-

-

The MANIFOLD coating chamber

-

Distributes the coating fluid evenly across the width of the die.

-

Ensures uniform flow and pressure of the coating material.

-

Can be designed in various shapes (e.g., T-shaped, coat-hanger) to optimize fluid distribution.

-

✅ Common manifold designs for extrusion and coating dies typically fall into three main categories: T‑slot (or T‑shaped), coat‑hanger, and multi‑manifold designs.

🔹 The Three Common Types of Manifold Designs

-

T‑slot (T‑shaped) manifold

-

Simplest design, often used for narrow width dies.

-

Melt enters a central channel and flows outward in both directions.

-

Cost‑effective but less uniform for wide coatings.

-

-

Coat‑hanger manifold

-

Named for its resemblance to a coat hanger.

-

Designed to balance pressure drop and flow distribution across the die width.

-

Commonly used in extrusion coating and film dies for uniform thickness.

-

-

Multi‑manifold design

-

Each polymer stream has its own dedicated manifold.

-

Essential for coextrusion where multiple layers with different rheological properties must be combined.

-

Provides precise control and minimizes interfacial instabilities.

-

⚙️ Why Manifold Design Matters

-

Uniform distribution of melt across the die lip ensures consistent film or coating thickness.

-

Reduced edge bead and waste improves efficiency.

-

Flexibility for multilayer structures allows manufacturers to process polymers with very different viscosities.

📌 Summary

In practice, three common manifold designs are widely recognized: T‑slot, coat‑hanger, and multi‑manifold. Each has its own strengths depending on whether the application is single‑layer extrusion, wide‑width coating, or complex multilayer coextrusion.

Would you like me to create a visual comparison diagram of these three manifold designs so you can use it in presentations or technical outreach?

Understanding these parts are essential, as they influence factors like flow rate and coating thickness, ultimately affecting product performance. By optimizing the design and function of these internals, manufacturers can achieve superior coating results for various applications.

Additional Features of a Slot Die - External

-

Die Hinges:

-

Allow the die to open and close for maintenance and cleaning.

-

Ensure precise alignment when the die is closed.

-

Facilitate easy access to internal components without disassembling the entire die.

-

-

Body Offset Block:

-

Used to adjust the position of the die body relative to the substrate.

-

Helps in fine-tuning the coating gap and alignment.

-

Essential for achieving optimal shear at the substrate coating interface.

-

-

Body Offset Shim:

-

Thin spacers placed between the die body and the offset block.

-

Used to incrementally adjust the overbite or underbite of the die lips.

-

Ensures precise control over the coating thickness and uniformity.

-

-

Feed Adapter:

-

Connects the coating fluid supply to the die manifold.

-

Ensures a smooth and consistent flow of the coating material into the die.

-

Can be designed for quick-clamp sanitary connections to facilitate easy changeovers.

-

-

Die Alignment Key:

-

Ensures proper alignment of the die components during assembly.

-

Prevents misalignment that could lead to uneven coating or damage to the die.

-

Critical for maintaining the precision and performance of the slot die.

-

-

Turning Bar:

-

Used to guide and redirect the substrate during the coating process.

-

Ensures smooth and consistent movement of the substrate under the die.

-

Helps in achieving uniform coating across the entire width of the substrate.

-

Additional Considerations

-

Material Compatibility: The materials used for the die components must be compatible with the coating fluid to prevent corrosion and contamination.

-

Precision Machining: High precision in the manufacturing of die components is essential for achieving uniform and defect-free coatings.

-

Maintenance and Cleaning: Regular maintenance and cleaning of the die are crucial to prevent clogging and ensure consistent performance.

Understanding these components and their functions is key to mastering slot die coating technology. Each part plays a critical role in ensuring the quality and uniformity of the coating, making it essential for industry professionals to be familiar with these details.

Applications of Slot Die Technology

Slot die technology is used across diverse industries for applications such as:

-

Lithium-Ion Batteries: Electrode and separator coatings.

-

Electrode Coating: Ensures uniform deposition of active materials for improved battery efficiency.

-

Separator Films: Achieves consistent insulation to enhance safety and performance.

-

-

Renewable Energy: Thin-film photovoltaic applications.

-

Photovoltaics: Uniform thin-film coatings increase light absorption and energy efficiency.

-

Fuel Cells: Precise application of catalysts for optimal chemical reactions.

-

-

Pharmaceuticals: Coating for transdermal patches and medical devices.

-

Transdermal Patches: Delivers consistent drug dosages through precise coating.

-

Diagnostic Strips: Uniform reagent coatings ensure accurate test results.

-

-

Electronics: Display and circuit manufacturing.

-

Flexible Displays: Ensures defect-free coatings for next-generation screens.

-

Printed Circuit Boards: Applies even coatings of solder mask or conductive inks.

-

-

Packaging: Adhesive, Barrier, Laminate, and Decorative coatings.

-

Food and Beverage Coatings: Precise application in multilayer constructions for adhesion and laminates to prevent moisture, condensation, oxygen, grease, and oil, enable tamper-proof sealing, and apply eco-friendly coatings.

-

Decorative Coatings: Enhance visual appeal and durability with gloss or matte finishes or holographic coatings.

-

You can find slot die coating technology in many other industries such as automotive, aerospace, marine, construction, architectural, electronics, touch screens, tapes and labels, solar, textiles, food, medical device, and much more!

Next Chapter: Learn About different types of coating technology and why slot die ranks above the rest

Why Choose Precision Die Systems?

With years of experience in precision coating, our team provides:

-

Custom Solutions: Every slot die is engineered to your exact application.

-

Proven Expertise: Trusted by top manufacturers across industries.

-

Ongoing Support: From design to installation and beyond.

-

Performance Standards:

-

Flatness/Straightness Deviation: Guaranteed 0.0001" or 2.54 microns, over full length and width. "Better upon request" sub-micron finish also available as application requires.

-

Lip Face and Flat Flow surface Deviation" Precision micro-ground and diamond lapped: 1-3Ra

-

Flatness Inspection Reporting

-

-

Proof of Process: Wet lab and Lease Die Equipment

Why Choose Our Slot Die Systems?

With years of experience in precision coating, our team provides:

-

Unparalleled Precision: Advanced engineering ensures maximum accuracy and repeatability for uniform coatings.

-

Durable and Versatile Construction: High-quality materials and optional customizations meet the demands of various industries.

-

Comprehensive Support: Included manuals, tool kits, and shipping containers simplify integration and maintenance.

Interested in learning how these features can improve your coating process? Contact us today to speak with an expert and request a personalized quote. Let us help you optimize your slot die system!

Ready to Take the Next Step?

If you're exploring slot die technology or looking for a reliable partner, Precision Die Systems is here to help. Our experts are ready to discuss your unique needs and recommend a solution tailored to your application.

Fill out our contact form today to learn more about how slot die technology can enhance your production process.

Learn More about

Precision Slot Die Types

Slide Curtain Dies

Cascade Dies

Triple Layer Fixed Slot Die

Ancillary Equipment for Coating Dies

Contact Us to Learn More

Whether you’re exploring slot die technology for the first time or seeking a partner to optimize your production, Precision Die Systems is ready to help.

Fill out our contact form to speak with one of our experts and find the perfect solution for your needs.